Here at Mattressman, we love to celebrate stocking a vast range of British-made sleeping solutions. Helping support British industry and improving the environment, our trusted suppliers do so much to bring the nation a great night’s sleep. Our blog this week is dedicated to British manufacturing, discussing our manufacturer’s outstanding qualities and values they uphold as well as talking about how mattresses are actually made…

The recipients of many Which? Best Buy awards, Silentnight has been innovating and producing quality and sustainable mattresses. Their eco range of mattresses include fibres made from recycled plastic bottles, and Silentnight has been recognised as a Superbrand for 13 years. That’s how you know they make the top of the range sleeping solutions! Take a look at Silentnight’s video below to see a typical day in their factory…

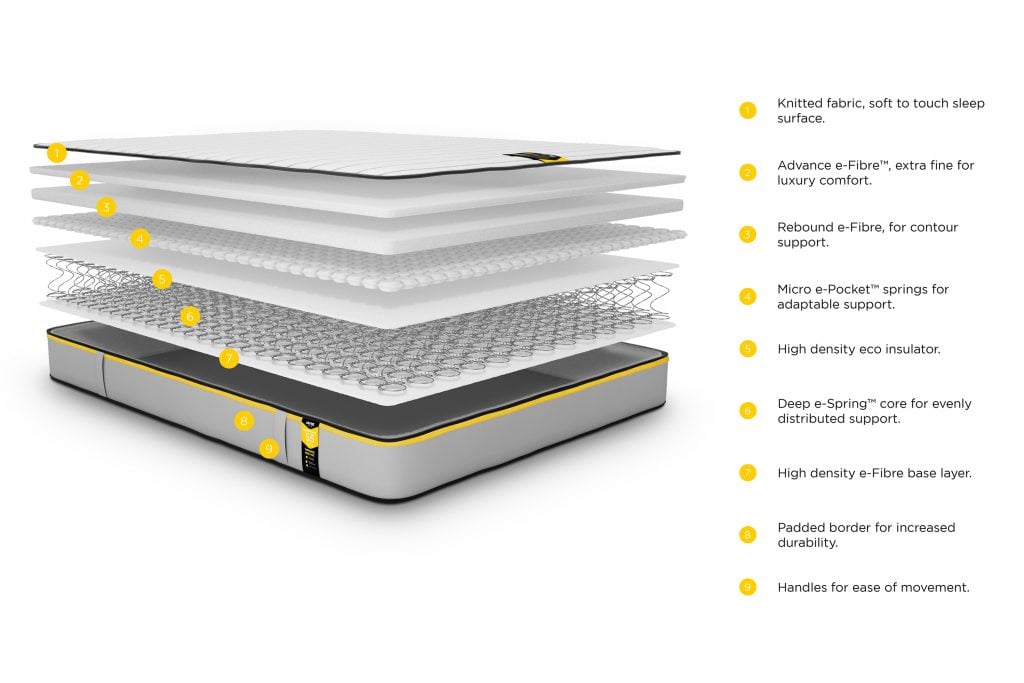

As you can see from JAY-BE’s Benchmark S5 mattress, the way they manufacture their mattress is much the same as described above, minus the tufting. The image shows the multiple layers they use to ensure the S5 is a comfortable mattress, of which all of the fibre fillings are sustainably sourced. These award-winning fibres expel 90% fewer carbon emissions and use 99% less water and land space. What’s more, their mattresses are entirely foam-free making use of recycled materials to produce sumptuous comfort.

Hypnos is known for breaking the norm. Eight years ago they became the first-ever carbon-neutral bed-maker in the world. Since then, they have partnered with Red Tractor to source sustainable materials from traceable, responsibly-sourced farms for all of their products. The wool used across their entire range is 100% British, which also gives farmers the initiative to invest in a more reliable and eco-friendly future.

Most sleeping solutions are constructed using pocket springs, although there are several options that consist of open coil spring system units. Open coil mattresses have individual springs that are all connected by a continuous wire, whereas pocket sprung mattresses have individual springs that are sewn into their own fabric pockets. This means they can move independently from one another, giving them the superior ability to mould to the contours of your body.

If the mattress is double-sided, mattress fillings and additional layers will be added to either side of the spring unit. High-quality sleeping solutions include multiple layers of fillings that can span from polyester, cotton, wool, mohair, pashmina, latex as well as manufactured layers such as Geltex or memory foam.

The next stage of mattress production usually involves laying the cover on top and using a method called tufting to secure all of the fillings and cover together. This is why you sometimes see button-like features on the surface of your mattress. However, this step is not necessary and every mattress manufacturer has a certain way of producing their sleeping solutions.

A border is stitched around the outside of the mattress, sometimes using reinforcements for edge-to-edge support of the mattress. Often, the stitching around the sides can be anywhere from 2 to 5 rows, depending on the quality of it.

Lastly, finishing touches such as mattress labels and handles are attached for convenience. Some manufacturers like to vacuum-pack the mattress for easy delivery, of which this would be the last step before it gets shipped.

If you want to make the most of British manufacturing, we currently have 20% off all British Bed Company mattresses. Simply use the code BBC20 to support British industry, as well as giving yourself a sumptuous new mattress.